What is Epoxy Tooling Board

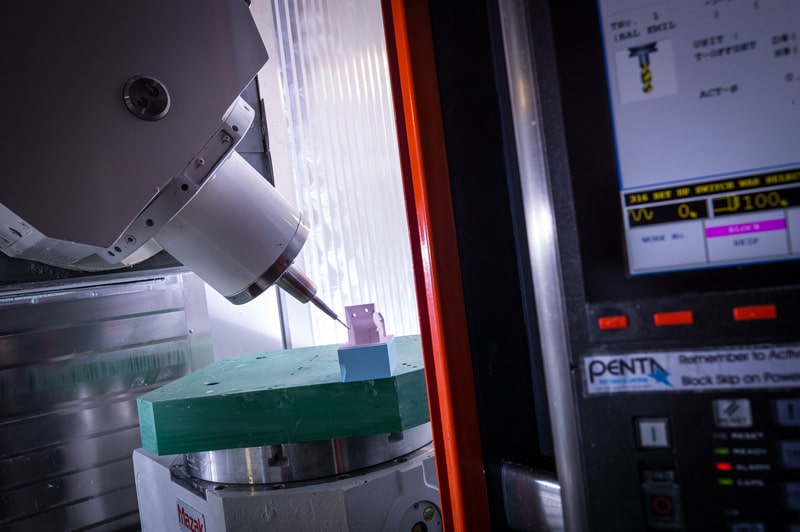

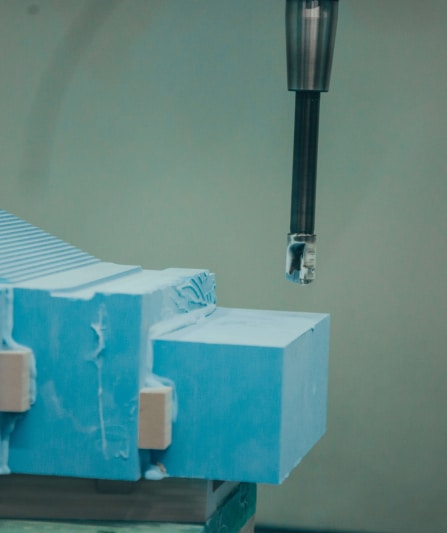

Tooling boards are the trusted material for many industries. Epoxy tooling board is a popular material for creating highly accurate moulds and composite patterns. It's frequently done with CNC machining and is used in high-temperature applications where dimensional stability is critical.

Any mould and pattern tools have to meet the demands of the marketplace, and you should be confident in the epoxy tooling board that you are using for your applications.

Why Use an Epoxy Tooling Board?

Epoxy tooling boards are widely used in most industries and are used for a variety of carbon fibre production and vacuum-forming materials. You can use it for prepreg tooling, moulds and composites as well. The reason it is chosen so often is because the epoxy tooling board is for use in high-temperature applications.

Choosing to use an epoxy tooling board means you are choosing a versatile product that is easy to work with. It strengthens resilience with exceptional internal consistency and allows you to continue to produce highly accurate moulds and patterns. Given that it's available in different board thicknesses up to 200 millimetres to suit your design plans, epoxy tooling board is the board of choice. It also an extremely low coefficient in terms of its thermal expansion.

Different Epoxy Tooling Boards

So that you can make an informed decision on which epoxy tooling board to choose, we have provided a list of the most common tooling boards that we use below. The information includes the benefits and common uses of each board so that you can make the right decision for your business.

BE978 Epoxy Tooling Board

The BE978 Epoxy Tooling Board is a premium, medium-temperature tooling material that’s designed to provide reliable and consistent performance. Known for its superior surface finish as well as its excellent dimension stability, it’s a fantastic tooling board for jigs and fixtures, patterns and master models.

Some of the benefits of using the BE978 Epoxy Tooling Board include a low coefficient of thermal expansion, excellent dimension stability results and being suitable for use up to 145°C.

You’ll find that the BE978 Epoxy Tooling Board is available in a range of board dimensions, as well as being compatible with a range of adhesives, surface coating, sealers and other release agents.

EP138 Epoxy Tooling Board

The EP138 Epoxy Tooling Board provides mechanically constant properties that are ideal for use as moulds and tools for any composites you may have. They benefit from being heat resistant and have a very fine surface structure.

Helpful for master patterns and for direct tooling or welding that requires operation at a high frequency. The EP138 Epoxy Tooling Board is often used in racing and vehicle construction due to its dimensional stability and fine surface structure. It’s a tooling board that’s ideal for the manufacturing of sports car components.

The tooling board also provides a low generation of dust during machining and a low coefficient of linear expansion.

TALK TO THE EXPERTS

Established in 1985, we have built a strong reputation for manufacturing excellent products within tight timescales and to extremely high tolerances. In order to achieve this, we use state of the art equipment and traditional, time honoured processes and skills.

Call us on:

01455 890 571

Email us at:

sales@pentapatterns.co.uk