Our CAD Capabilities

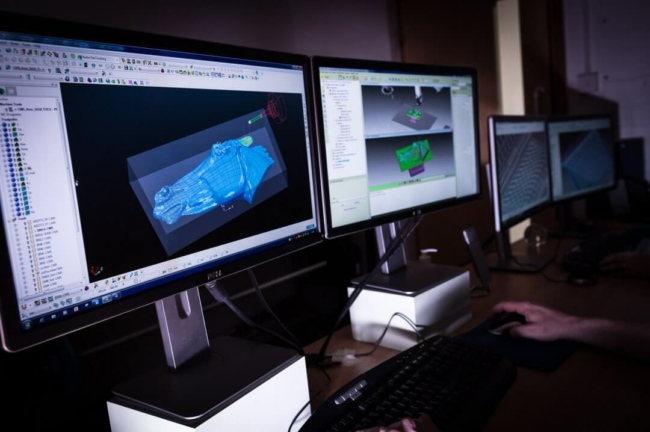

Penta Pattern & Model uses Autodesk’s PowerShape, a powerful CAD system for complex parts and modelling for manufacture. This system allows our engineering team to create complex 3D geometry for multi-axis, high-speed CNC machining with ease.

Product Design

Turn your ideas into manufacturable products with our CAD engineering and design services. We can work from your idea or concept and work with you through the complete design process from scratch.

Engineering Design

When provided with a CAD design of the final product, we can design and engineer all of the other elements required to achieve the end result through manufacture such as the patterns and moulds.

Reverse Engineering

We can reconstruct an existing part or assembly by gaining dimensional information of the object via 3D scanning. We then work through the usual design process in the opposite direction to arrive at the product design specification. During the process, vital information about the design concept and manufacturing methods is discovered.

Surface Modelling

We use Geomagic Design X for editing from scan data and mesh data. This allows us to define and sculpt the highest quality surfaces which is a sought after attribute in the motorsport and automotive industries.

TALK TO THE EXPERTS

Established in 1985, we have built a strong reputation for manufacturing excellent products within tight timescales and to extremely high tolerances. In order to achieve this, we use state of the art equipment and traditional, time honoured processes and skills.

Call us on:

01455 890 571

Email us at:

sales@pentapatterns.co.uk