THE PROCESS

Storage

Our large walk-in freezer allows us to ensure that rolls of prepreg material are kept at a minimum of -18°C.

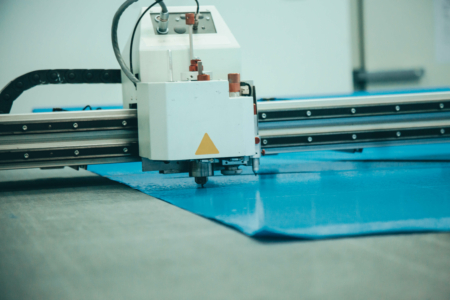

Kit Cutting

Material is cut to shape using our conveyorised kit cutting machine. We use the latest nesting software to ensure that materials are optimised to reduce waste while still maintaining aesthetic and functional fibre orientations.

We can provide kit-cutting as a stand-alone service, if required.

Laminate

Our specialist laminators will visually inspect the mould surface and each individual ply for imperfections before methodically laying plies into the mould. They will continue this process until they achieve the required thickness with local area plies, bootlace strips and inserts as required.

Vacuum Bag

Once the laminating stage is complete, the moulds are wrapped in a release film and breather cloth before being carefully placed into a vacuum bag. Air is then expelled through a vacuum connector which pulls the composite material closer to the surface of the mould, creating better consolidation.

Cure

The bagged moulds are placed into one of the two autoclaves at our factory, the Ø1.5m x 3m Italmatic autoclave or the Ø500mm x 1200mm(L) Dwell 280 autoclave and put through a pressurised cure. During the curing process, the resin heats up and flows across the surface of the mould and eventually cures in a hardened solid state. We do also offer autoclave cure cycles as a stand-alone service, if required.

For out of clave systems and post curing capabilities, we use a large curing oven measuring 2.5W x 2H x 2.1D.

Demould

Composite components that have been cured are removed from the bagging and carefully extracted from the mould, inspected and sent to finishing. The mould is then thoroughly cleaned and prepared to be used for another laminating stage, if required.

TALK TO THE EXPERTS

Established in 1985, we have built a strong reputation for manufacturing excellent products within tight timescales and to extremely high tolerances. In order to achieve this, we use state of the art equipment and traditional, time honoured processes and skills.

Call us on:

01455 890 571

Email us at:

sales@pentapatterns.co.uk