Creative freedom

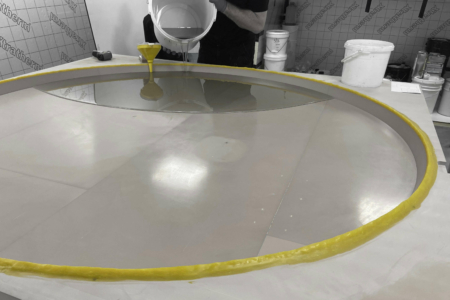

Our knowledgeable team are flexible and can work with you throughout the resin casting process to achieve great results. You are welcome at the workshop at any time and can also come and get stuck in with us! Our facility allows you to have full creative freedom so you are able to do things like mix colours and add details to give your pieces that personalised touch.

Detail can be applied either before the casting process by encapsulating elements within the resin or applied after with our wide range of finishes. We are also developing ways of encapsulating natural and waste products to create captured moments and reduce / reuse waste materials.

Materials, pigments and paints

There are a number of different materials, pigments and paints available for you to use alongside resin. This includes, but is not limited to:

- Gold leaf

- Foils

- Paint

- Metallic shimmer powders

Topping these textures with optically clear resin can create truly stunning pieces of artwork. You can also have translucent, pigmented or opaque designs.

Different textures can be achieved upon request, the possibilities are endless! Just contact us and one of our experts can advise you and share a full sample list with you.

TALK TO THE EXPERTS

Established in 1985, we have built a strong reputation for manufacturing excellent products within tight timescales and to extremely high tolerances. In order to achieve this, we use state of the art equipment and traditional, time honoured processes and skills.

Call us on:

01455 890 571

Email us at:

sales@pentapatterns.co.uk