5 Axis Machines

Machining can be provided as either a stand alone service or can be combined with the processing of composite parts for inserts and/or detailed precision features such as slots, holes, threads or other requirements.

Our workshop consists of four full 5-axis machines ranging in size:

- CMS – 2600x1500x1200mm

- CMS – 3600x1800x1200mm

- Mazak – 3000x1000x700mm

- Mazak – 500x500x500mm

Extensive Range of Materials

We offer an extensive 5-axis CNC machining service and are capable of processing a range of materials including, but not limited to:

- Polyurethane model boards

- Epoxy model boards

- Aluminium

- Polystyrene

- Timber

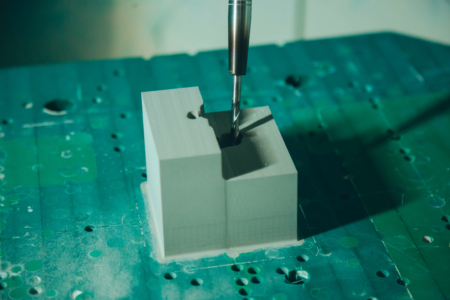

What is 5 Axis CNC Machining?

5-axis CNC machines are defined by their ability to rotate around the part (or rotate the part itself) while machining it. This differs from a standard 3-axis CNC machines in that instead of just relying on lateral movement, 5 axis machines can effortlessly handle machining from various angles, eliminating the need for constant material movement by operators.

With 5-axis machining, manual rotation is replaced by machine precision, resulting in improved accuracy, higher production rates, and the capability to manufacture larger, more intricate parts in less time compared to other CNC machines.

TALK TO THE EXPERTS

Established in 1985, we have built a strong reputation for manufacturing excellent products within tight timescales and to extremely high tolerances. In order to achieve this, we use state of the art equipment and traditional, time-honoured processes and skills.

Call us on:

01455 890 571

Email us at:

sales@pentapatterns.co.uk