3D scanning technologies

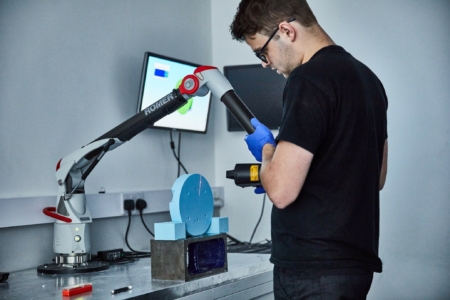

Our dedicated inspection facility includes:

- An Artec Leo Wireless 3D Scanner

- Two 1.5m Hexagon Romer Absolute Arms (portable)

- One 4m Hexagon Romer Absolute Arm

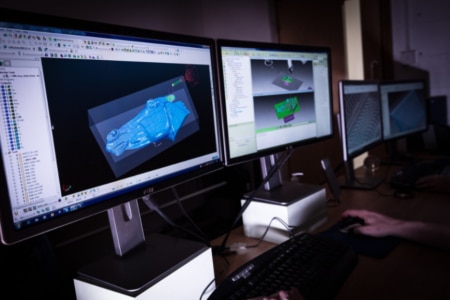

This state-of-the-art technology provides the ability to capture exceptionally accurate measurements, regardless of the environment. We use Autodesk Power inspect and Artec Studio software for all scanning and inspection purposes which makes inspecting large, complex and layered parts simpler. Then for editing from scan data and mesh data, we use Geomagic Design X. This allows us to define and sculpt the highest quality surfaces.

Example 3d Scanning Projects

Explore a selection of case studies of our work. Among these are some spectacular examples of projects where our 3D scanning service played a crucial role. We're proud to have worked with some of the worlds pre-eminent sculptors and artists on pieces that can be seen across the globe.

Which 3d Scanning Technology is best for you?

3D laser scanning is a versatile technology employed across multiple industries. Its applications range from surveying and mapping to 3D modeling. In contrast, photogrammetry is a technique that transforms 2D photographs into 3D models. When deciding between these technologies, it is crucial to consider the specific requirements and purposes for which the equipment will be utilized.

TALK TO THE EXPERTS

Established in 1985, we have built a strong reputation for manufacturing excellent products within tight timescales and to extremely high tolerances. In order to achieve this, we use state of the art equipment and traditional, time honoured processes and skills.

Call us on:

01455 890 571

Email us at:

sales@pentapatterns.co.uk