Why is Carbon Fibre Becoming More Common in the Manufacture of Cars?

Carbon fibre has been used within sports and racing cars since the 1970s. But it was only when carbon fibre proved its durability in the 1981 Monza Grand Prix that the popularity of the material rapidly accelerated. During the Grand Prix, John Watson, driving the McLaren MP4/1, crashed in the carbon fibre monocoque cabin; when he incredibly walked away from the accident, proving the carbon fibre cabin to be stronger than its aluminium counterpart, the industry’s fears were extinguished and the material became highly sought due to its low weight and high performance.

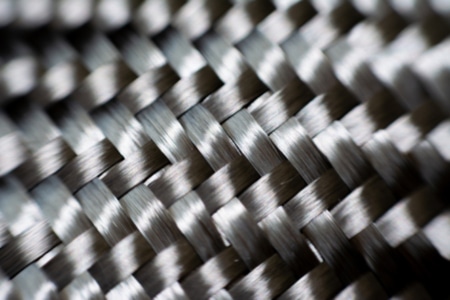

The popularity of carbon fibre is primarily due to its strength to weight ratio. The material boasts an impressive strength which competes with the likes of steel, but remains lightweight like a plastic, making it uniquely fuel efficient for automotive applications. Additionally, it has great chemical and corrosion resistance, is stiff, and has high fatigue strength.

The rising commonality of carbon fibre in automotive applications can also be ascribed to developments in research and manufacturing. Carbon fibre is becoming increasingly accessible thanks to continual research around the manufacture of the product, making it more cost and time-efficient for higher volume applications. As well as this, developments in conceptual research around how carbon fibre can be integrated into automotive vehicles has led to wider ranging applications.

For these reasons, carbon fibre is having a growing presence in the automotive industry, for both racing and mainstream applications.

Where Do Car Manufacturers Use Carbon Fibre?

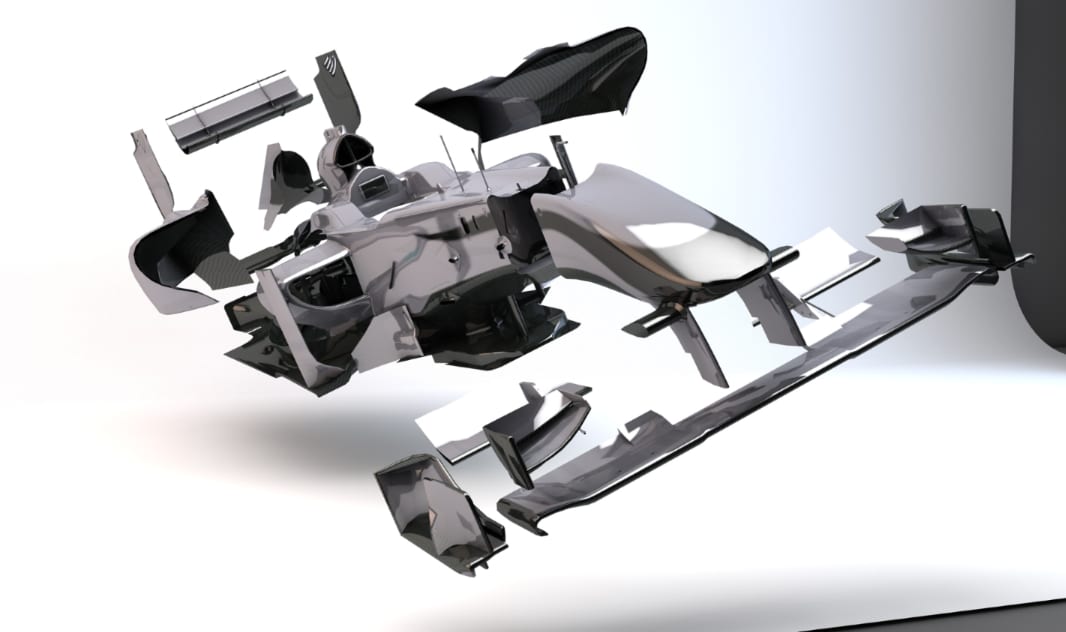

With the advancements made in the use of carbon fibre in automotive industry vehicles, there has also been advancements in where carbon fibre can be used safely within a vehicle.

The list of carbon fibre automotive parts continues to expand for automotive and racing applications; for instance, the Toyota Prius PHV is fitted with a carbon fibre reinforced plastic tailgate, which is claimed to be the first instance of this in a mass-produced car.

Carbon fibre can be incorporated into many areas of a car, including:

Body Components

One place carbon fibre can be used is in the body of the car; though the body of the car differs with each make, it can largely be defined as the engine section and cover, the saloon, and the boot. Carbon fibre applications for the body of the car include the car wing (or fender) and engine hood; spoilers; car doors; and the roof.

Structural Components

Due to the strength of carbon fibre, it can be safely used in structural components of a car, meeting the regulations for performance in a crash, such as energy absorption, as well as under mechanical stresses. Structural applications of carbon fibre include the chassis, roof frame and windshield frames - reinforcing the ABC pillars, plus side sills and more.

Components for EV High-Voltage Batteries

With electric vehicles signalling the future of the automotive world, carbon fibre has begun to be incorporated into components for high-voltage batteries, which are important for increased performance, cost-efficiency, and compatibility with a variety of car models. Carbon fibre is suitable for high-voltage batteries due to meeting regulations for resistance to fire, thermal management, electromagnetic interference shielding, and more.

Wheels

In 1971, Citroën incorporated carbon fibre into their wheels, marking one of the first uses of carbon fibre in the automotive industry. Today, carbon fibre wheels, despite their expense, can be incorporated into vehicles by car enthusiasts for improved handling and driving experience, reduced road noise, and faster acceleration.

Tyres

Similarly to the wheel, the tyres of a car can utilise carbon fibre reinforcement for improved durability, handling, and driving experience. The use of carbon fibre in car tyres is typically seen in racing applications, where carbon fibre reinforcement offers greater contact with the road surface for improved handling.

Interior Design

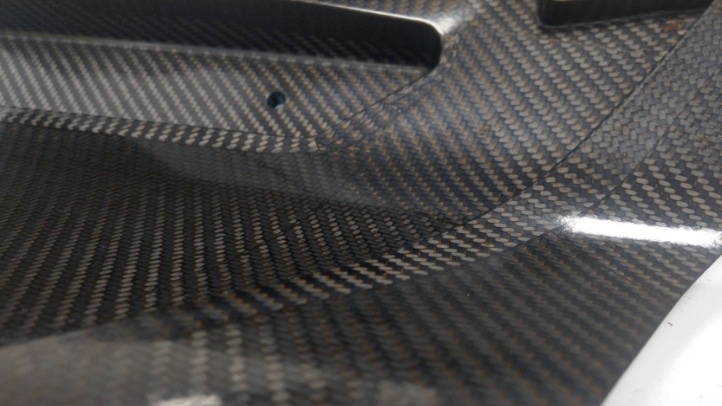

The distinctive aesthetic of carbon fibre makes it a desirable material for interior wraps and components, especially on luxury cars where customisation is sought. Interior components including the steering wheel and gear stick, door linings, and more, can all incorporate carbon fibre where aluminium and plastic are traditionally used. Carbon fibre now finds itself among the most popular materials and finishes available.

Carbon Fibre in Cars Examples

From one-of-a-kind supercars, to your everyday road vehicle, there are many examples of carbon fibre automotive parts, as seen below.

BMW i3

This electric vehicle is a smaller commuter car which features a carbon fibre frame and bodywork. The i3 has since been discontinued, however marks a great occasion for the introduction of a mainstream, smaller carbon fibre car.

GMC SIerra 1500

This full-size truck utilises carbon fibre in the truck bed for enhanced durability and low weight.

Audi a8

The Audi A8 features a carbon fibre reinforced plastic rear panel and parcel shelf, demonstrating how carbon fibre is making its way into mainstream, sedan cars.

McLaren SEnna

The exclusive hypercar McLaren Senna marks the first of the sports cars on this list. It utilises carbon fibre across its design, with the ability to customise the car further with a complete carbon fibre body.

Aston Martin Valkyrie

The aerodynamic Valkyrie sports car is the most expensive vehicle on this list, and features a carbon fibre tub, body and chassis.

The Future of CARBON FIBRE in cars

Whilst carbon fibre is not a new addition to supercars and racing cars, with its performance-boosting characteristics long praised, we are beginning to see the use of carbon fibre trickle down into more mainstream vehicles as it becomes more accessible for high volume production.

Related Articles About Carbon Fibre

TALK TO THE EXPERTS

Established in 1985, we have built a strong reputation for manufacturing excellent products within tight timescales and to extremely high tolerances. In order to achieve this, we use state of the art equipment and traditional, time honoured processes and skills.

Call us on:

01455 890 571

Email us at:

sales@pentapatterns.co.uk