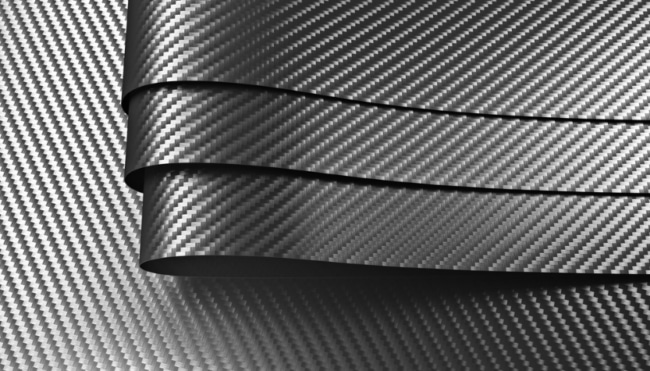

What is carbon fibre ?

Carbon fibre composite material is a woven material which is embedded in resin. It rose to popularity in the 1960s, as an incredibly strong and durable material which can be used in a variety of applications, from the frame of a bicycle to automotive parts. Carbon fibre also has a low density, and good thermal and chemical stability, making it suitable for a variety of applications across aerospace, defence and construction sectors amongst others.

Carbon fibre is created from organic polymers, which can be manufactured alongside other materials to increase the desired properties of the carbon fibre, before being drawn into long strands called tows. The tows are about the thickness of a tenth of a human hair and must be bundled together. Following this, the tows are heated in a vacuum so that they do not burn, undertaking a process called carbonisation. These bundles can then be woven and embedded in resin to create a composite material – carbon fibre.

Why does carbon fibre cost so much?

Carbon fibre prices remain high despite its popularity and its suitability across a range of industries. So, why does carbon fibre cost so much if it has such great potential?

When compared to other materials on the market, carbon fibre can be seen as one of the more expensive ones. Several factors influence its cost, including:

- The manufacturing process

- Requirement of skilled labour to create

- A recently introduced product on the market

Because carbon fibre is relatively new to the market, research is ongoing to cut the costs of its production – unlike many metals and plastics, which utilise a production refined over decades and even centuries. The manufacturing process is lengthy and complex, requiring skilled engineers to complete.

However, the price of carbon fibre has significantly reduced compared to the start of the century, and continues to reduce as research evolves.

Performance and return on investment (ROI)

Whilst the performance of carbon fibre has been proven in numerous applications, its return on investment must be decided on an individual basis. For those looking to utilise carbon fibre, the advantages of the material must be weighed up against its manufacturing costs to calculate whether the return on investment is viable.

For example, automotive (in particular, Formula One and racing applications) and aerospace sectors may find a higher ROI investing in carbon fibre because of its light weight and durability over other materials such as aluminium. In this scenario, the performance of carbon fibre is more advantageous than its expense.

TALK TO THE EXPERTS

Established in 1985, we have built a strong reputation for manufacturing excellent products within tight timescales and to extremely high tolerances. In order to achieve this, we use state of the art equipment and traditional, time honoured processes and skills.

Call us on:

01455 890 571

Email us at:

sales@pentapatterns.co.uk