What is Recycled Carbon Fibre (RCF)?

Recycled carbon fibre refers to existing carbon fibre material that has been given new life and purpose, as opposed to the use of virgin material.

The process of recycling carbon fibre is complex; it cannot be melted and reshaped like some metals and plastics can. Instead, it must be recycled through mechanical, thermal or chemical methods, depending on the type of carbon fibre involved.

Despite this, the need for recycling carbon fibre remains prevalent due to the amount of waste created by virgin CF. This waste during fabrication processes ultimately ends up in landfill, raising environmental concerns and triggering new legislation addressing the reduction of carbon fibre in landfill as a result.

Innovations Within the Carbon Fibre Industry

The development of carbon fibre demonstrates a move away from traditional metals and plastics and there have been several more developments within the industry since this time.

What is Carbon Fibre?

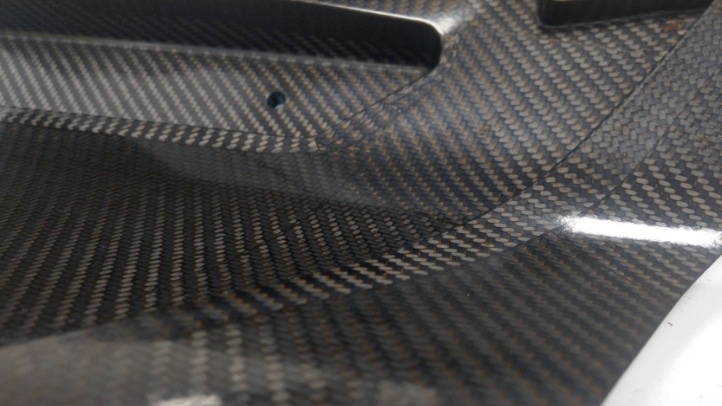

Carbon fibre refers to woven fibres set in a resin. The fibres are created from organic polymers which are manufactured alongside auxiliary materials to enhance desirable properties; they are then drawn into strands before undergoing heating, known as carbonisation. The heated strands are finally woven and set in resin.

The end result is an extremely stiff and strong, lightweight material.

Carbon Fibre

Of course, the creation of high-performance carbon fibre marks a significant opportunity for outperforming traditional materials, such as steel and plastic. Its durability and long lifespan, plus enhanced properties, makes carbon fibre a desirable alternative.

Flax Fibre

Flax fibre is a natural fibre which has been developed as a substitute for carbon fibre in select applications. Being biodegradable with a low environmental footprint, flax fibre is greener than carbon fibre, however it does not compete with the tensile and impact strength of carbon fibre.

Recycled Carbon Fibre

Recycled carbon fibre is the latest industry development, providing a more environmentally-conscious way of using carbon fibre, with great reductions in carbon emissions.

The Benefits of Recycled Carbon Fibre

The development of carbon fibre demonstrates a move away from traditional metals and plastics and there have been several more developments within the industry since this time.

- Alleviates demand for carbon fibre

- Lowers costs associated with producing carbon fibre

- Reduces the amount of carbon fibre in landfill

- Reduces costs associated with collecting and landfilling waste carbon fibre

The Drawbacks

When utilising recycled carbon fibre, one of the struggles is being able to replicate the integrity of virgin carbon fibre. This is due to the shortening of the fibre length in recycling the material, which leads to issues surrounding the properties, strength, stability and durability.

This signals that there is still some way to go with the development of recycled carbon fibre, especially in demanding environments such as motorsport and renewable energy (wind turbines).

The Uses of Recycled Carbon Fibre

The applications of recycled carbon fibre are varied across industries, including motorsport, furniture and more.

Motorsport

Recycled carbon fibre is used across the automotive and the motorsport industries. RCF enables these industries to meet environmental goals and reduce carbon emissions.

An example of this is McLaren, who was the first to incorporate carbon fibre on their sports cars in 1981; McLaren further used flax bio-based fibre in 2020 and has most recently begun to trial the use of recycled carbon fibre on F1 sports cars.

Furniture

Luxury furniture can be created using recycled carbon fibre, with the ability to design and manufacture all types of furniture – from chairs and tables to unique artwork pieces.

Recycled carbon fibre offers strength and aestheticism in this application.

Other Industries

Recycled carbon is being researched and developed in light of other industries with high use for carbon fibre. This includes the aircraft and renewable energy sectors, in particular, wind energy, with carbon fibre used in the fabrication of wind turbines.

TALK TO THE EXPERTS

Established in 1985, we have built a strong reputation for manufacturing excellent products within tight timescales and to extremely high tolerances. In order to achieve this, we use state of the art equipment and traditional, time honoured processes and skills.

Call us on:

01455 890 571

Email us at:

sales@pentapatterns.co.uk