What is 3D Laser Scanning ?

3D laser scanning is a 3D scanning service that uses lasers to create models of real-world objects. It is a process that can be used for various applications, such as construction, design, and manufacturing. This technique has been around since the 1980s but it has recently grown in popularity due to its accuracy and speed.

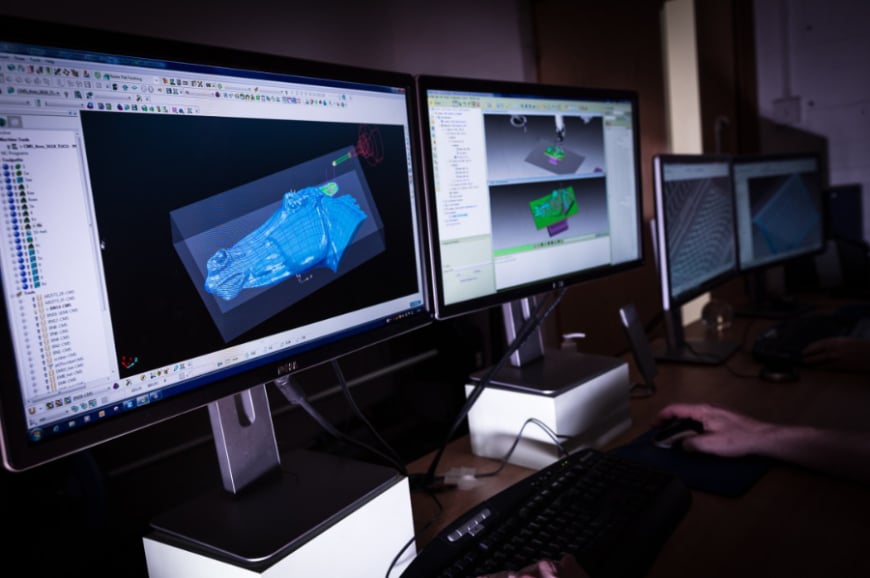

3D laser scanning is an efficient way to create accurate digital replicas of physical objects. This technology creates models from any surface that can be used in the design process and in the manufacturing process. The laser scanner operates by firing millions of light pulses, counting the number of objects each light pulse strikes, and calculating the distance between them. It is sometimes referred to as 3D scan or point cloud scanning because it creates an accurate point cloud which can be viewed from all angles or in different perspectives. The data collected by the scanner are then processed into CAD files which are commonly used in the manufacturing process.

3D Laser Scanning Advantages and Disadvantages

The 3D laser scanner can accurately measure your product to one-tenth of a millimetre and create 3D CAD files. This technology has made using this type of scanning as convenient and quick as using a webcam to quickly capture an object.

3D laser scanning is changing the way that businesses are approached. As an emerging technology that uses a 3D laser scanner to create highly accurate models of the physical world, it improves the quality of design, construction and other sites by offering tangible proof of property boundaries. The technology also helps to reduce errors in calculations and provide a better understanding of projects with less environmental impact.

As much as it has benefits such as creating accurate replicas of products, making the construction process more efficient, using the CAD model to generate prototype parts, and providing data for analysis, there are also disadvantages. One of which is the amount of time it takes to produce a 3D model. It is a time-consuming process because of the many steps required.

What is 3D Photogrammetry ?

3D photogrammetry is a process that takes digital photos and converts them into 3D models. This technology is used in many areas such as construction, engineering, archaeology and more. Using 3D photogrammetry in your business will help you to understand your existing products better and to make improvements where needed. It also helps you to prepare for the future by creating new designs for new product lines or even just for advertising purposes.

As 3D photogrammetry is a scanning technology that captures high-resolution digital images of real-world objects and places, it is often used in fields such as engineering, architecture, and manufacturing. 3D Photogrammetry can be used for many things in the business world. It can help businesses get a better understanding of the space they are working with before they start building or remodelling their property. 3D Photogrammetry can also be used to produce 3D models for use in animation, games, and virtual reality applications.

Photogrammetry Advantages and Disadvantages

Photogrammetry is a 3D imaging technology that uses digital cameras to capture and reconstruct three-dimensional spatial information. It is widely used in the field of engineering, architecture, and construction.

Photogrammetric data can be directly transferred into software for use in design, engineering, construction, manufacturing, surveying, environmental management, education, and so on. Then, photogrammetric data can help improve productivity too. One of the huge advantages of it is that it is cost-effective and produces high quality results.

3D photogrammetry is a great way to create 3D models because it doesn't require you to use expensive software or moldmaking materials. The disadvantages of working with this technique are that the quality may not be as good as traditional methods like CAD or laser scanning. It can also be the case that incorrect measurements may lead to inaccurate 3D models.

TALK TO THE EXPERTS

Established in 1985, we have built a strong reputation for manufacturing excellent products within tight timescales and to extremely high tolerances. In order to achieve this, we use state of the art equipment and traditional, time honoured processes and skills.

Call us on:

01455 890 571

Email us at:

sales@pentapatterns.co.uk